Unique and unrepeatable

An acid stained floor is, in fact, a truly custom-made floor that is designed and built according to the designer’s and customer’s requirements. Acid stained floors are created using carefully selected acids, derived from metallic salt compounds, which penetrate into the concrete and react with the free lime, chemically changing the colour to produce unique and permanent variegated effects. Ideal Stains create variable, contrasting or translucent effects that are very similar to the nuances of natural stone or the aged appearance of a weather worn coating. The result is unique for each surface and cannot be duplicated with other dyeing materials. Concrete loses its banal appearance and takes on a rich and natural beauty.

Why choose an acid stained floor?

It is unique and modern

Acid stained concrete has caught the attention of design studios, architects, landscape architects, designers and decorators for incorporation into the design of private houses, lofts, public spaces, shops, showrooms, restaurants, nightclubs, pubs, pavilions, exhibition halls, hotels and shopping centres. Thanks to the adaptability of Ideal Work® products and technologies, each individual project is evaluated and designed according to the type of end use envisaged and the type and extent of traffic it has to support. Depending on these criteria and the customer’s specific requirements, flooring thicknesses, type of texture (rough or smooth), the type of surface finish and other technical variables of flooring are decided.

Practical and easy to maintain

Commercial installations shine with easy-to-maintain colourful floors. In terms of durability and abrasive resistance, the colour of acid stained concrete is of a better quality than concrete surfaces treated with acrylic dyes or other types of resins that can peel, fade or disintegrate quickly. Thanks to their chemical reaction with concrete, Ideal Stain® acids become part of the surface. They are not subject to fading, spoiling, cracking or peeling.

Acid-Stain is not only applicable on floors

Acid-Stain can also be applied to stairs and other vertical surfaces. Architects now have a solution to produce unique and unforgettable environments which can be created and personalised to meet specific requirements by Ideal Work® applicators.

Latest projects made with Acid-Stain

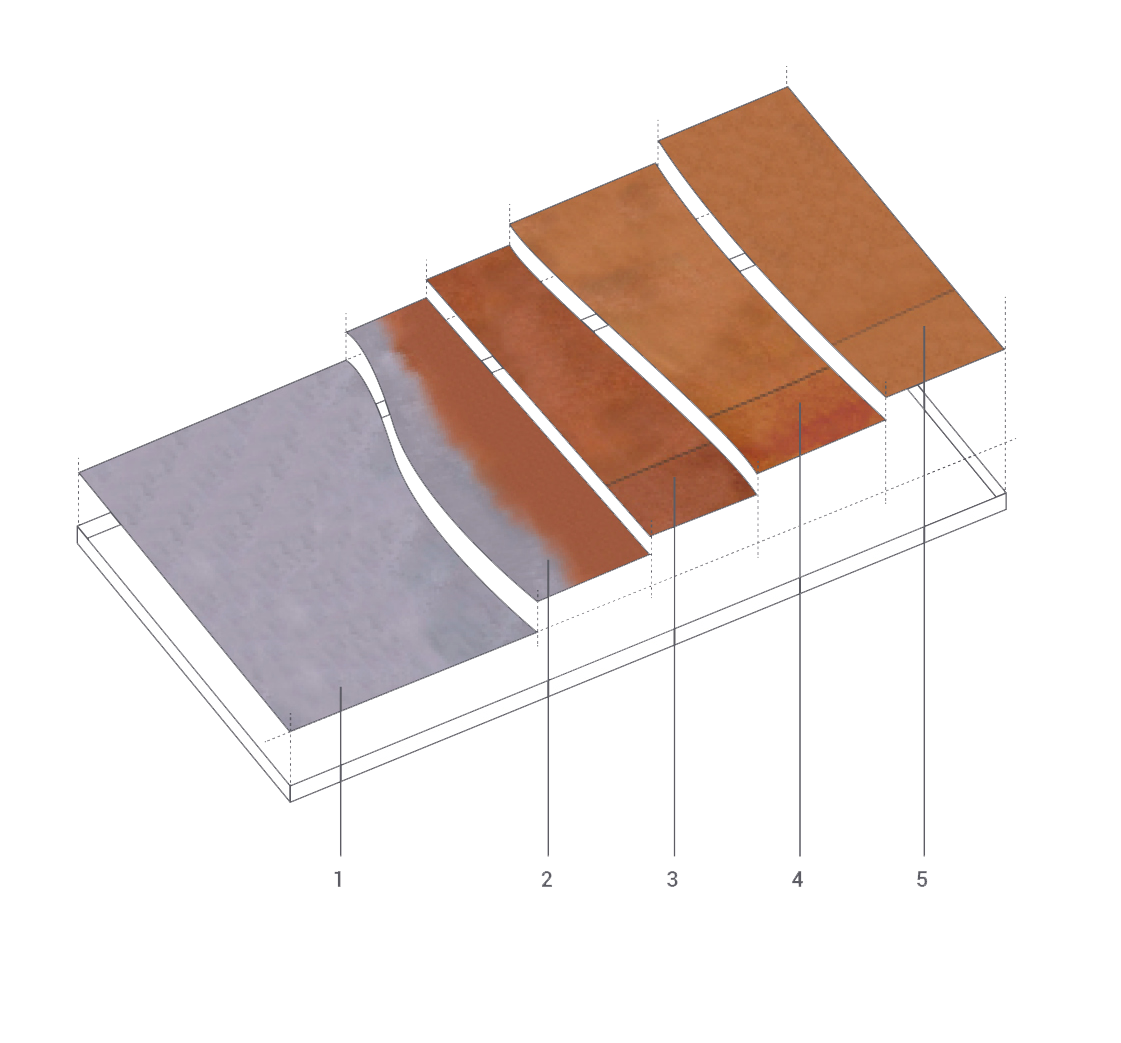

How

1. Surface preparation

2. Application of Ideal Stain

3. Washing

4. Washing with Neutralize

5. Application of a protective sealer

FAQ

Absolutely not. Ideal Stains® are formulated to react only during the 4 hours following application. Once the application is finished and the flooring has been treated with surface protection, even where there is underfloor heating, no substance is released that could be harmful to health. Tests carried out discovered that acid stained surfaces come within class A+ related to the quality of air measured inside interior environments.

Absolutely, yes. It will be necessary to carefully assess the thickness available for creating the floor in order to choose the most suitable technical solution: concrete, Betontop or Microtopping. In addition, acid stained or Nuvolato floors created in concrete or Betontop give better results, in terms of heat conduction, than other flooring systems (see comparable table).

As with all types of concrete slabs, acid stained floors are also jointed. The cutting acts to encourage the natural contractions of the concrete and so create movement joints. It is the task of the Ideal Work installer to define the design and location of the cuts. These can also be incorporated into a designed pattern, masking the true purpose of the joint. Once complete, the joints can be filled with special coloured resins that can be the same colour as the floor.

With continuous surfaces made in concrete or similar products, it is possible that cracking can appear due to the contraction of the concrete and other external influences. The installer undertakes, in any event, to adopt all necessary strategies to limit the appearance of cracks, although these can appear for reasons other than the workmanship including through settlement of the structure. In the event that cracks do appear, it is possible to take action, repairing the cracks with specific products in order to conceal them, obtaining a pleasing aesthetic result.

Cleaning an acid stained floor is very simple. A damp cloth is sufficient to clean the surfaces with the addition of a little neutral detergent for floors (for example PERFETTO! Ideal Work, a dedicated detergent for decorative Ideal Work surfaces). It is recommended to periodically treat the surface with protective products based on self-polishing waxes dispersed in water (for example, Ideal Cera) or beeswax (for example EASY WAX). Detergents based on soap, acid, ammonia, chlorine or any abrasive detergent product are absolutely prohibited. It is recommended to use only NON AGGRESSIVE, neutral PH detergents.

Ideal Work offers a wide range of protection. The choice of the right protection depends on the requirements of the end user and the surface location. In principle, even if the surface treatment effectively protects the concrete from rapid penetration of accidentally spilled liquids, it is well to remember that all liquids, especially those most used in the domestic environment such as wine, oils, vinegar, ice cream and coffee, must be eliminated quickly from all surfaces before they have time to penetrate to any depth.

Certainly, it is possible to stain stairs and other vertical surfaces. When dealing with projects that require special processes, it is important firstly to determine the most suitable technical solution with your Ideal Work installer in order to obtain the final result you require.

The thickness of the floor depends on the traffic and the type of loads that the floor must support. Based on this information, the thickness and type of concrete to be used can be established. As a guide, the thicknesses used in normal conditions are the following: 7-10 cm, exterior or interior residential pedestrian only areas, 13-15 cm, light vehicle traffic areas (cars), 18-20 cm, medium-to-heavy vehicular traffic (cars-lorries). In the case of lower thicknesses of between 5-6 cm, rather than creating a substrate in concrete, it would be wise to use BETONTOP, a special multifunctional additive suitable for creating backgrounds with specifications similar to concrete, but suitable for low thicknesses. These values are entirely indicative and should be used as such. It is the job of the designer to establish the thickness and resistance of the concrete based on the loads (even occasional). It will, however, be the responsibility of your Ideal Work installer to advise and assist you in choosing the finish most suitable for your requirements.

Absolutely, yes. As monolithic concrete flooring, they are extremely resistant to walking, impact and vehicle traffic. Due to the chemical reaction with the concrete, Ideal Stain becomes integral to the surface. Acid stained surfaces are not subject to fading, scratches, stripping or cracking and are as resistant as the concrete slab itself.

Technically, a Nuvolato floor made with the hardener Ideal Floor Pewter (light grey based titanium aggregate) is the base surface for later acid stain treatment with Ideal Stain acid based stains. It can therefore be stated that the Nuvolato flooring is the starting point for acid stained flooring. Structurally, they do not change: assessment of the thickness, resistance to abrasion and compression, protective and maintenance treatments are practically the same. The difference is aesthetic: the colours and the effects are completely different. Nuvolato floors feature pastel colours, greys and whites; the texture of the finish is softer and tends to be more uniform compared to a simple acid stained concrete floor, which is notable for the greater intensity of colours, unique textures and irregularities similar to those of leather.

Generally, yes: acid stained flooring can also be created on an existing screed. In such cases, it will be important to assess the quality and type of screed on which the new flooring will be adhered. Based on the thickness available, Ideal Work offers various technical solutions: MICROTOPPING, suitable for application on thicknesses of 3-4 mm; TOPFLOOR, specifically for use creating flooring with a thickness of 1-2 cm and BETONTOP, suitable for thicknesses between 2 and 6 cm. It will be the responsibility of your Ideal Work installer, however, to advise and assist you in the choice of flooring most suitable for your requirements.

Absolutely, yes. In the case of exterior applications, it will be fundamental to assess, together with the installer, the finishing of the mother slab which must be slip-resistant, as well as the most suitable protective treatment.

The coloured acidic solution containing metallic salts comes in contact with the cement flooring and reacts with the alkalinity (usually the lime or cement content) of the concrete itself, creating the colour. The result is unique for every surface and depends on many variables: the chemical composition, the mix design, porosity, age, texture and colour of the concrete, the number of applications and other factors.

Acid stained floors are unique surfaces with a definite personality, featuring unrepeatable plays of colour and textures. They are designed to create variegated finishes. It is possible to partly reduce the intensity and the variegations of the effects by adding water to the product during the mixing and application phase. If a more uniform effect is sought ,however, it is generally recommended to choose a Nuvolato floor.

Ideal Stains are available in 7 standard colours: Fern Green, Amber, Terracotta, Brown, Turquoise, Ebony and Jade. It is possible to change the colour or reduce the intensity by mixing several colours together and diluting the product with water. The acids are not resins, varnishes or paints: the colour is created, in fact, by the chemical reaction that takes place between the alkaline part of the surface and the acidic part of the product. If a specific colour is desired, it is recommended to choose a Nuvolato floor.