Beautiful and accessible

Ideal Wall has been developed by Ideal Work® to create high-end decorative vertical finishes at an affordable price. Walls, columns, panels, stairs, decorative structures and other surfaces take on a more sophisticated, original and dramatic look. Ideal Wall is made up of selected sands, Portland cement, UV-resistant inorganic oxides and specific additives to improve the working process, level of waterproofing and adhesion.

Why choosing Ideal Wall

It’s quick to create

Once IDEAL WALL has been applied and the plaster has reached the appropriate consistency, the specific “texture” is created by means of special rubber moulds; depending on the type of mould, the texture may be only superficial. On the other hand, contours of stones or bricks can be made with other Ideal Work® tools. There are also some moulds that create both the texture and contours of stone, so that it is only necessary to do the finish the next day. Within 8-18 hours, depending on the temperature, you can finish the carvings or create new ones with the help of the Ideal Work® professional tools. After completing the finish, or within 1-2 days, continue with the staining process using RAINBOW COLOURS, professional Ideal Work® dyes.

It is custom design friendly

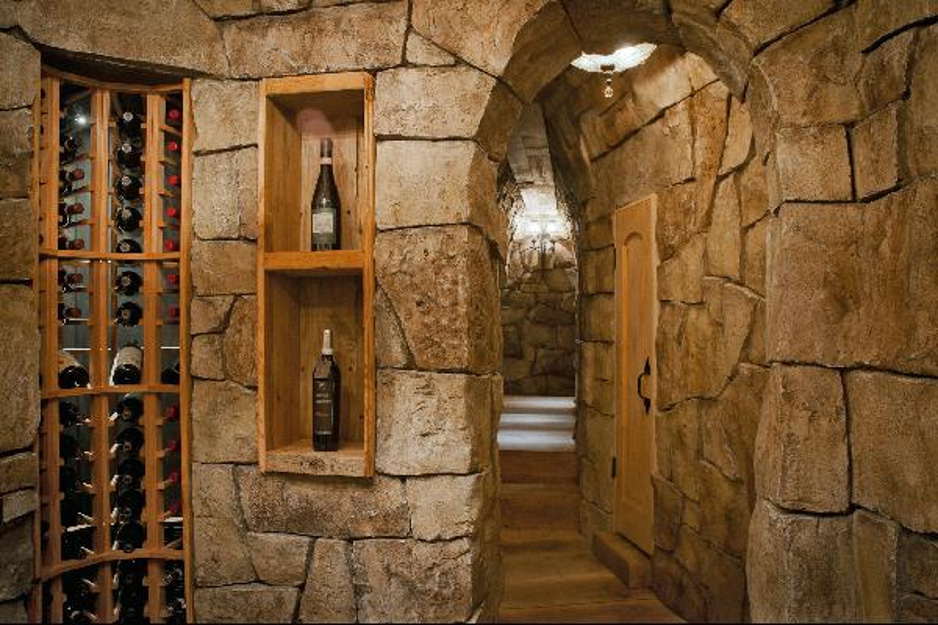

Traditional, sober, sophisticated, antique – with Ideal Wall you can recreate all the effects you want on the wall: to embellish homes, public places, shopping centres, managerial or production sites. From ancient brick to rock, from volcanic rock to stone, from wood to slabs: there is virtually no limit to the solutions that can be achieved thanks to the wide range of moulds Ideal Work® has created.

It is extremely adaptable

The product can be applied directly onto brick, concrete, stone surfaces and, after proper substrate preparation, onto other bases such as plasterboard, polystyrene, wood and metal supports. The special formula permits a greater workability that makes applying the plaster easy and fast, even for the less experienced.

Latest projects made with Ideal Wall

How

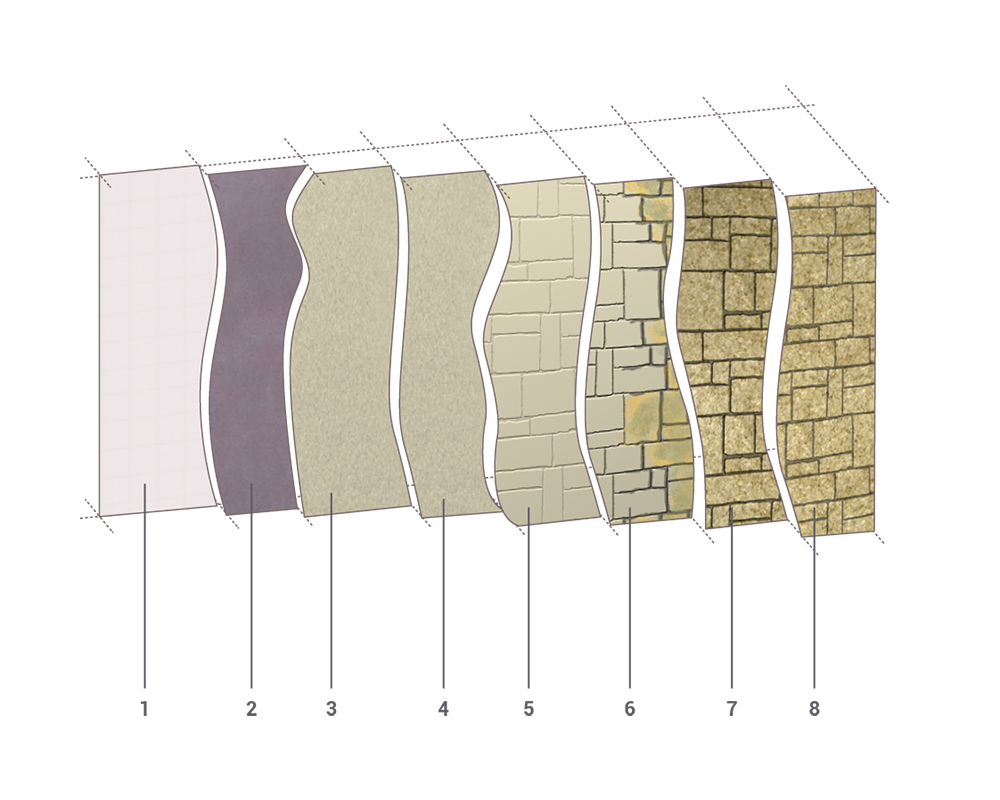

Surface preparation

1-2. Ideal Wall-Eco may be applied directly on concrete surfaces, bricks, rocks and other surfaces such as plasterboard, polystyrene, wood and metallic surfaces.

Stamped wall application

3. Mixing of Ideal Wall eco with water.

4. Application of Ideal Wall eco in thicknesses from 1 to 3 cm.

5. Once the mixture is laid and dry, application of Liquid release agent and stamp the surface by using moulds and Ideal Work professional equipment.

6. The next day proceed with the cleaning and finishing of the texture by using professional tools.

7. Colouring with Colour rainbow.

8. Application of protective sealer Ideal Sealer Medium (for exterior applications) or resin Ideal Acrylic (for interior applications).

FAQ

Based on the conditions of the support and the type of texture chosen (large or small stones, bricks, rock etc.), installation times can vary. As a guide, to create a wall of 20 square metres, the installation times vary between 2 to 3 working days.

After a careful assessment of the substrate and adequate preparation, the stamped wall can be laid on any type of surface. It will, in any event, be the responsibility of your Ideal Work installer to make recommendations on the feasibility or otherwise of the operation and help you in the choice of the most suitable solution for your requirements.

The stamped wall is classified, in accordance with EC regulations, as coloured, single-layered plaster for exteriors. The material is therefore suitable for applications outside and is resistant to freeze / thaw cycles. In such cases, it is wise to choose the most appropriate protective treatment.

Technically, it is also possible to apply the plaster on horizontal surfaces but the amount of traffic the new surfaces will be subjected to should be considered. In the event of pedestrian traffic, an alternative solution can be used, such as Stamped Floors or similar.

The stamped wall does not require special maintenance but must be sealed. It is recommended to wash the surfaces with cold water and sweep with a soft brush. Based on the climatic conditions (for example, proximity to the sea or very cold areas), it is recommended to apply a new coat of protective resin over the years.

OPTION 1: The stamped wall is the only Ideal Work solution that also lends itself to “do-it-yourself” use. Usually, the corporate policy is that specific training courses held at the headquarters must be attended before buying the material.

OPTION 2: Ideal Work will directly identify the authorised installer in your area. It is very important to assign the work to a specialised Ideal Work installer in order to obtain a quality result. Ideal Work trains its own installers through periodic courses, held by specialist personnel, for the twin purpose of training new installers who want to begin to install the products and improving the techniques of those who already use them.

The thickness of the plaster varies from 1 cm to 3 cm, based on the specifications of the support and the type of stamp chosen. Some stamps, in fact, have very deep textures and require greater thickness.

The stamped wall is classified, in accordance with EC regulations, as coloured, single-layered plaster for exteriors. The resistance to compression is 3,4 N/mm², comparable with a traditional plaster for exteriors.

The colouring of the stamped wall can be done by fully colouring the plaster with the dyes of the Color pack-c (available in 24 colours) and superficial shading with the Rainbow dyes (available in 11 colours). The combinations are practically endless. Indeed, it is possible to mix several colours together, diluting them with water, or modify the chromatic effects by changing the application technique.

By providing adequate preparation of the support, on both surfaces, the material can be suitable for such application. In any event, it will be the responsibility of your Ideal Work installer to give you recommendations on the feasibility or otherwise of the operation and assist you in the choice of the most suitable solution for your requirements.

In addition to the wide range of stamps shown in Ideal Work stamps catalogue, the Ideal Wall plaster can also be worked manually with the use of pre-shaped stamps. The freehand finishing technique is very complex and must be done by highly qualified personnel. In order to obtain a quality result, it is recommended to assign the work to a specialised Ideal Work installer.

Absolutely not. The stamped wall is made using a premixed plaster that is applied directly on the substrate and later pressed with special stamps that recreate the shapes and textures of stones, bricks, rocks and even wood.