Construction joints

Ideal Joint construction joints provide the perfect solution for concrete floors where bays are poured at different times.

Ideal Joint construction joints provide the perfect solution for concrete floors where bays are poured at different times. The Ideal Joint system is not just a ‘good for every occasion’ system, there are in fact three different types of joint, each designed to resolve a specific problem. All are characterised by their high reliability, extreme ease of placement and use and ability to react to movement in two directions

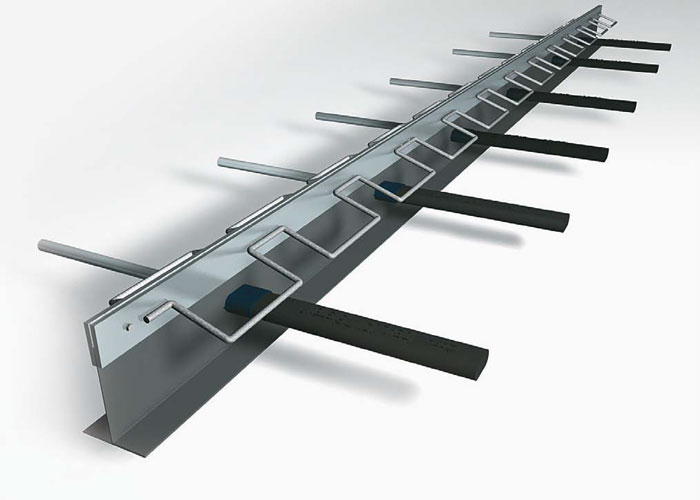

IDEAL JOINT CLASSIC

It is a preformed joint for industrial concrete flooring with two-way rotation. IDEAL JOINT CLASSIC is characterised by its extremely easy installation process and extremely reliable operation. IDEAL JOINT CLASSIC is suitable for use in all slabs made from reinforced concrete in lieu of traditional steel dowel construction joints built on site. It can also be easily used to make intermediate expansion joints, in the case of extremely large castings or in the case of radiant floor heating with the possibility of sizing up the distance between the slabs according to the expected thermal expansion.

Have a look at the catalogue to discover the benefits of the product.

IDEAL JOINT PERFORMANCE

It is a preformed joint for industrial concrete flooring with bidirectional rotation designed specifically for use in the presence of considerable stress and heavy traffic such as in logistics warehouses, transport hubs, etc… IDEAL JOINT PERFORMANCE is suitable for use when replacing traditional steel dowel construction joints made on site in concrete slabs which are subject to heavy traffic, such as logistics warehouses, traffic hubs, etc … and, in all cases, where the frequent impact of heavy metal objects against the joint edges is foreseeable. IDEAL JOINT PERFORMANCE combines high shock resistance and wear resistance to the advantages and performance of the bidirectional construction joints of the Ideal Joint line. IDEAL JOINT PERFORMANCE is supplied on site already assembled and ready to use and does not require any additional work after the laying and casting of the floor.

Have a look at the catalogue to discover the benefits of the product.

IDEAL JOINT DUAL

It is a preformed joint that is specifically designed for the production of concrete slabs on which ceramic coatings can be applied. DUAL JOINT is characterised by its extremely easy and quick installation process and very high operational reliability. DUAL JOINT is specifically designed for use in commercial flooring, exhibition areas or in all situations where load requirements require the creation of a concrete slab measuring at least 10 cm thick, whilst the aesthetic and functional requirements or design choices require the construction of a ceramic coating. DUAL JOINT allows you to create, with only one element, both the joint in the base concrete slab and the corresponding expansion joint in the ceramic coating.

Have a look at the catalogue to discover the benefits of the product.